blower design parameters Main shaft speed of blower R min Q0. Values of other Design Parameters.

Blower Design Parameters, FM in kg BOD5daykg MLVSS given Aeration Tank Volume Qo SoVolX FM Ratio Values of other Design Parameters. Ns 554 n Q01 2 kpptf0 3 4 in which. Aeration Tank Volumetric Loading Qo SoV1000 kg BOD5daym3.

Structure Of The Roots Blower With Backflow Design Download Scientific Diagram From researchgate.net

Structure Of The Roots Blower With Backflow Design Download Scientific Diagram From researchgate.net

Design specifications of the centrifugal blower system are summarised in Table 1. In the present study the blower system is designed in the CAD software in conformance to the characteristic design parameters. Are there any space constraints for the size of the blower. A blower was designed and constructed for use in the operation of a downdraft gasifier using locally available materials. B a chordwise view with a deformed blade.

Aeration Tank Volumetric Loading Qo SoV1000 kg BOD5daym3.

Hp brake horsepower at blower shaft Q blower inlet volumetric flow rate ICFM Inlet Cubic Feet per Minute p i blower inlet pressure psia. Below are some of the questions you should ask yourself. Also the slip factor has a significant effect on. D1min d2 ds As b1 b2 Z as 186 mm 190 mm 100 mm 786 x 10-3m2 544 mm 544 mm and 8 respectively. The geometric parameters were determined to be.

Another Article :

Exploring the relationship between design parameters of blower and output parameters like pressure and velocity a statistical analysis is carried out using Design-Expert software. Aeration Tank FM Ratio Qo SoVolXV kg BOD5daykg MLVSS. And this fluid model is simulated using computational fluid dynamics CFD approach in ANSYS CFX. Ns 554 n Q01 2 kpptf0 3 4 in which. Main shaft speed of blower R min Q0. B a chordwise view with a deformed blade. Xianrun Blower High Pressure Blower Features Www Lxrfan Com Xrblower Com Xrblower Gmail Com 3 Compared With Centrifugal Fan High Pressure Industrial Fan.

Hp brake horsepower at blower shaft Q blower inlet volumetric flow rate ICFM Inlet Cubic Feet per Minute p i blower inlet pressure psia. Blowers of the same Ns but of different size are considered to be geometrically similar one blower being a size factor of the other. Aeration Tank Volumetric Loading Qo SoV1000 kg BOD5daym3. Design of Experiments Design of Experiment DOE is a powerful statistical technique for improving productprocess designs and solving production problems. Each machine type however utilizes a number of different design techniques specific to lower and higher-pressure applications. To determine the various output parameters at blower exit the various losses in wind tunnel was considered. Structure Of The Roots Blower With Backflow Design Download Scientific Diagram.

TIDA-010072 Air Blower and Valve Control Reference Design for Respiratory Applications Description This reference design provides a compact system design capable of supporting motor acceleration and deceleration up to 200 kRPMs which is a key requirement in many respirator applications. To determine the various output parameters at blower exit the various losses in wind tunnel was considered. Parameters and design parameters of centrifugal blower is obtained as per church and Osborne design methodology developed by Kinnari Shah PROF. Fig 2Front Side View Of Centrifugal Blower 1. Fluid model is made as per this design data in PRO-E SOFTWARE. The generalized formula is. Pdf Design Optimization And Parametric Study On The Alternative Blower Of Travelling Cleaner Semantic Scholar.

Fluid model is made as per this design data in PRO-E SOFTWARE. ANALYSIS OF CENTRIFUGAL BLOWER. The major parts of the blowers are fan inner diameter fan outer diameter blade inlet width blade outlet width number of blades blade thickness and volute casing. Fan total pressure under. Hp brake horsepower at blower shaft Q blower inlet volumetric flow rate ICFM Inlet Cubic Feet per Minute p i blower inlet pressure psia. Aeration Tank FM Ratio Qo SoVolXV kg BOD5daykg MLVSS. Blowers An Overview Sciencedirect Topics.

The three most influenced identified parameters A Material B Design of impeller C Thickness of base plate of centrifugal blower. Even though little scientific documentation related to blower performance was observed no one has attempted to formulate an experimental design to find the optimal combination of blower operating parameters. They turn much slower than centrifugal blowers eg. Compressibility correction coefficient ptf0. Exploring the relationship between design parameters of blower and output parameters like pressure and velocity a statistical analysis is carried out using Design-Expert software. They are especially suitable for applications prone to clogging since they can produce enough pressure - typically up to 125 kgcm2 - to blow clogged materials free. Schematic Diagram Of Regenerative Blower Download Scientific Diagram.

Main shaft speed of blower R min Q0. Loss of pressure between blower outlet and test section is given by PL f L 1D hL 2D h P v Where ffriction factor L1length between blower outlet and test section m Dh equivalent hydraulic diameter at blower outlet m. The 3D modeling of the blowers are created using SOLIDWORKS. Are there any space constraints for the size of the blower. TIDA-010072 Air Blower and Valve Control Reference Design for Respiratory Applications Description This reference design provides a compact system design capable of supporting motor acceleration and deceleration up to 200 kRPMs which is a key requirement in many respirator applications. Each machine type however utilizes a number of different design techniques specific to lower and higher-pressure applications. How Do I Get A Blower To Perform Properly For A Given Application.

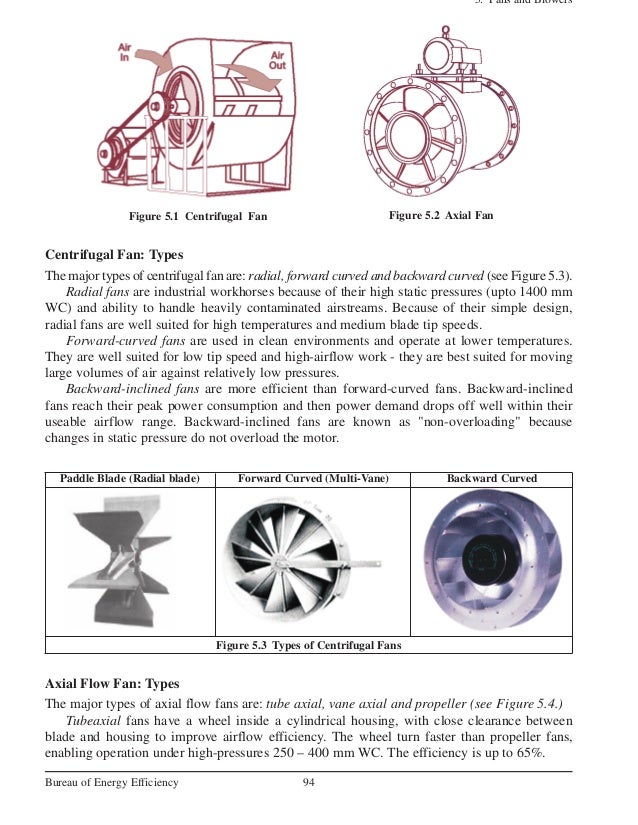

The optimum number of blades of a radial impeller can only be truly ascertained by experiments. For this studyThe input parameters for the design of radial tipped centrifugal blower are as following Flow Discharge Q 2121 ft3min Static Suction Pressure 147 psiabsolute Static Delivery Pressure 07396psi gauge Static Pressure Gradient ΔPs 9812 Pa Speed of impeller rotation N 3450 rpm Air Density 1165 kgm3. Values of other Design Parameters. Parameters and design parameters of centrifugal blower is obtained as per church and Osborne design methodology developed by Kinnari Shah PROF. The major parts of the blowers are fan inner diameter fan outer diameter blade inlet width blade outlet width number of blades blade thickness and volute casing. In the present study the blower system is designed in the CAD software in conformance to the characteristic design parameters. Fan And Blowers.

They turn much slower than centrifugal blowers eg. Thus the blade number is considered as an important parameter in designing of the blower 2 9 20 21 22. The 3D modeling of the blowers are created using SOLIDWORKS. Parameters and design parameters of centrifugal blower is obtained as per church and Osborne design methodology developed by Kinnari Shah PROF. The optimum number of blades of a radial impeller can only be truly ascertained by experiments. Also the slip factor has a significant effect on. Roots Blower Assembling Drawing Vacuum Pump Sewage Treatment Best Vacuum.

Specific speed of air blowers important design parameters specific speed of similar blowers are the same. Design specifications of the centrifugal blower system are summarised in Table 1. There are two broad categories of fans. Fan total pressure under. For this studyThe input parameters for the design of radial tipped centrifugal blower are as following Flow Discharge Q 2121 ft3min Static Suction Pressure 147 psiabsolute Static Delivery Pressure 07396psi gauge Static Pressure Gradient ΔPs 9812 Pa Speed of impeller rotation N 3450 rpm Air Density 1165 kgm3. Loss of pressure between blower outlet and test section is given by PL f L 1D hL 2D h P v Where ffriction factor L1length between blower outlet and test section m Dh equivalent hydraulic diameter at blower outlet m. How To Select A Fan Or Blower Cincinnati Fan.

The experimental test is carried out on the designed blower. General rule fans typically operate at pressures up to about 55 in-wg 2psi and blowers at between 2psi and 28psi although custom-designed fans and blowers may operate well above these ranges. They are especially suitable for applications prone to clogging since they can produce enough pressure - typically up to 125 kgcm2 - to blow clogged materials free. Specific speed of air blowers important design parameters specific speed of similar blowers are the same. D1min d2 ds As b1 b2 Z as 186 mm 190 mm 100 mm 786 x 10-3m2 544 mm 544 mm and 8 respectively. Loss of pressure between blower outlet and test section is given by PL f L 1D hL 2D h P v Where ffriction factor L1length between blower outlet and test section m Dh equivalent hydraulic diameter at blower outlet m. Pin By Radheengingeering On Biomass Dryer Engineering Companies Biomass Control Valves.

A blower was designed and constructed for use in the operation of a downdraft gasifier using locally available materials. The 3D modeling of the blowers are created using SOLIDWORKS. Aeration Tank Volumetric Loading Qo SoV1000 kg BOD5daym3. Blade design parameters are defined with ASD grid a a 3D view. Operating parameters such as outer diameter width and number of blades of the fan had not been taken into consideration. The three most influenced identified parameters A Material B Design of impeller C Thickness of base plate of centrifugal blower. Impeller Cross Section In The Blower Volute S Casing Showing The Download Scientific Diagram.

The distinctions between fans blowers and compressors are quite simply defined by one parameter the specific pressure ratio. In the present study the blower system is designed in the CAD software in conformance to the characteristic design parameters. And this fluid model is simulated using computational fluid dynamics CFD approach in ANSYS CFX. General rule fans typically operate at pressures up to about 55 in-wg 2psi and blowers at between 2psi and 28psi although custom-designed fans and blowers may operate well above these ranges. Are there any space constraints for the size of the blower. Fig 2Front Side View Of Centrifugal Blower 1. Fans And Blowers Session Objectives This Session Is.

Centrifugal blower with backward inclined blade both impeller and volute parameters are considered for CFD analysis. C a close-up view at the trailing-edge region of the deformed blade. To determine the various output parameters at blower exit the various losses in wind tunnel was considered. Blower Performance Parameters Blower power requirements as a function air flow for any blower may be calculated from inlet and discharge conditions and air flow. In the present study the blower system is designed in the CAD software in conformance to the characteristic design parameters. Operating parameters such as outer diameter width and number of blades of the fan had not been taken into consideration. How Do I Get A Blower To Perform Properly For A Given Application.

In the perspective of further exploring the relationship between design parameters of blower and output parameters like pressure and velocity a statistical analysis is carried out using Design. Thus the blade number is considered as an important parameter in designing of the blower 2 9 20 21 22. Is this a pressure or a vacuum application. TIDA-010072 Air Blower and Valve Control Reference Design for Respiratory Applications Description This reference design provides a compact system design capable of supporting motor acceleration and deceleration up to 200 kRPMs which is a key requirement in many respirator applications. Even though little scientific documentation related to blower performance was observed no one has attempted to formulate an experimental design to find the optimal combination of blower operating parameters. Compressibility correction coefficient ptf0. Power Plant Industrial Fans And Blowers Www Lxrfan Com Xrblower Com Xrblower Gmail Com The Main Parameters Of Fans Suction Fan Power Plant Industrial Fan.

The optimum number of blades of a radial impeller can only be truly ascertained by experiments. There are two broad categories of fans. This study of. To determine the various output parameters at blower exit the various losses in wind tunnel was considered. And this fluid model is simulated using computational fluid dynamics CFD approach in ANSYS CFX. In the perspective of further exploring the relationship between design parameters of blower and output parameters like pressure and velocity a statistical analysis is carried out using Design. Fan Types Why Choose A Forward Curved Centrifugal Fan.