batch distillation design and operation Design And Operation Optimisation. Conventional Batch Distillation 58 421 Rayleigh Model Model Type I 58 422 Short-cut Model- Model Type II 59 423 Simple Model- Model Type I11 63 424 Rigorous Model -Model Type IV 68 425 Rigorous Model wt Chemical Reactions -Model Type V 79 ih 43 Models for Unconventional Batch Distillation 85 431 Continuous Column for Batch Distillation 85 432 Inverted Batch.

Batch Distillation Design And Operation, Control variables operating decisions and objectives are identified. There are many papers in the literature dealing with the optimisation of the operation of batch distillation for a given column design and for a single separation duty Farhat et al. Batch distillation refers to the use of distillation in batches meaning that a mixture is distilled to separate it into its component fractions before the distillation still is again charged with more mixture and the process is repeated.

Ginuary Ginuary2017 Ginfacts Gin Ginspiration The Gin Making Process As An Infographic From The Brilliant Gin Making Process Gin Distillery Distillation From pinterest.com

Ginuary Ginuary2017 Ginfacts Gin Ginspiration The Gin Making Process As An Infographic From The Brilliant Gin Making Process Gin Distillery Distillation From pinterest.com

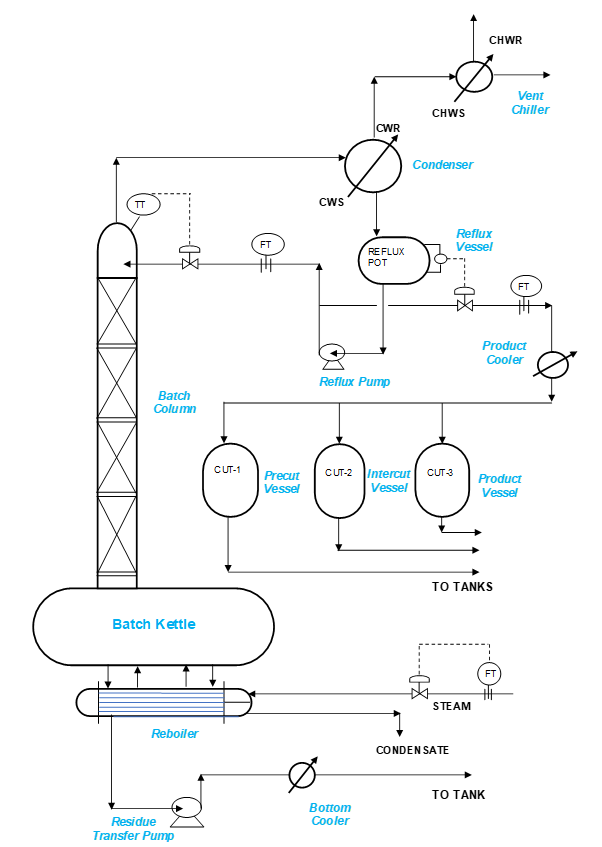

Following these initial attempts of the reboiler and the McCabe-Thiele operating line Westerbergs group at Carnegie Mellon University quasi-steady-state assumed have been rederived for developed the concept of the reactive difference point7 reactive batch distillation columns. The primary objective in a batch distillation is to minimize both the batch cycle time and heat input by optimizing the number of stages and reflux ratio to achieve the required separation. The primary objective in a batch distillation is to minimize both batch cycle time and heat input by optimizing the number of stages and reflux ratio to achieve the required separation 3 5. The efforts include both the design and operation of batch distillation. 1 SCOPE This Engineering Guide sets out the factors which can influence the design of a batch still facility.

The process variables are interdependent as determined by the mass and energy balances and the mode of operation.

Reboiler size batch size and heat transfer area 4. The primary objective in a batch distillation is to minimize both the batch cycle time and heat input by optimizing the number of stages and reflux ratio to achieve the required separation. Wankat discusses batch distillation an important part of the production of seasonal or low capacity and high-purity chemicals and is a very frequent separation process in the pharmaceutical industry. Design and Operation presents excellent important contributions of many researchers from around the globe including those of the author and his co-workers. Control variables operating decisions and objectives are identified.

Another Article :

Batch distillation refers to the use of distillation in batches meaning that a mixture is distilled to separate it into its component fractions before the distillation still is again charged with more mixture and the process is repeated. Due to the dynamic behavior of the operation of batch distillation that leads to more difficult operation such efforts have been done to attain the desired specifications and at the same time to increase the operability. This flexibility allows one to deal with uncertainties in feed stocks or product specifications. This paper considers for the first time the simultaneous multi-objective optimisation of design and operation of batch distillation as well as of batch hybrid distillationpervaporation processes. Design of batch distillation. In batch distillation columns the feed may be charged into the reboiler at the beginning of the operation and then heat is provided at the reboiler to evaporate part of the liquid to generate a vapor that rises through the column until it reaches the condenser where it is converted to liquid and collected at the reflux tank. Batch Distillation With Rectifying Column Download Scientific Diagram.

The design consisted of a process flow diagram a layout and a summary of all equipment required for the operation of the distillery. Modeling aspects are discussed and a suitable representation for operations is introduced. Logsdon and Biegler 1993. The design of a batch distillation column is similar to the design of a continuous distillation column in that the following main design parameters must be determined. Introduction 276 KB Request Inspection Copy. Following these initial attempts of the reboiler and the McCabe-Thiele operating line Westerbergs group at Carnegie Mellon University quasi-steady-state assumed have been rederived for developed the concept of the reactive difference point7 reactive batch distillation columns. Distillation Of Whiskey And Rum Distilled Sunshine In 2021 Distilling Alcohol Home Distilling Reflux Still.

Number of stages or plates in the column section and thereby the column height 2. Design And Operation Optimisation. Imperial College Press Jan 1 2004 - Technology Engineering - 396 pages. Modeling aspects are discussed and a suitable representation for operations is introduced. Batch distillation column as shown in Figure 51a. The primary objective in a batch distillation is to minimize both batch cycle time and heat input by optimizing the number of stages and reflux ratio to achieve the required separation 3 5. Mother Earth Alcohol Fuel Chapter 8 Still Plans Moonshine Still Moonshine Still Plans Whiskey Still.

The primary objective in a batch distillation is to minimize both the batch cycle time and heat input by optimizing the number of stages and reflux ratio to achieve the required separation. Whilst this is a particularly valid approach when the vapor-liquid equilibria are unknown it relies on both experience and availability of suitable plant to get a practical separation scheme. 4 Operation under finite reflux ratio without solvent. There are many papers in the literature dealing with the optimisation of the operation of batch distillation for a given column design and for a single separation duty Farhat et al. Control variables operating decisions and objectives are identified. Introduction 276 KB Request Inspection Copy. Batch Distillation Column Operation Controls Chemengghelp.

The process variables are interdependent as determined by the mass and energy balances and the mode of operation. And used this concept to provide simplified design With respect to the limiting operation conditions. Email protected Design and Operation of Batch Extractive Distillation with Two Reboilers 287 1 Operation under total reflux without solvent-feeding 00 50. Operational design and improvement of conventional batch distillation and middle-vessel batch distillation 771 Table 1. Due to the dynamic behavior of the operation of batch distillation that leads to more difficult operation such efforts have been done to attain the desired specifications and at the same time to increase the operability. The design of a batch distillation column is similar to the design of a continuous distillation column in that the following main design parameters must be determined. Homemade Reflux Distilling Columns Distilling Alcohol Moonshine Recipes Alcohol Still.

Thus the design and mode of operation of many existing batch stills has evolved on a empirical basis with only limited reference to conventional distillation engineering calculation. However the design of a batch distillation system is more complicated because of the transient nature of the operation and because there may be several ways in which the overall separations required may be accomplished. Reboiler size batch size and heat transfer area 4. Conventional Batch Distillation 58 421 Rayleigh Model Model Type I 58 422 Short-cut Model- Model Type II 59 423 Simple Model- Model Type I11 63 424 Rigorous Model -Model Type IV 68 425 Rigorous Model wt Chemical Reactions -Model Type V 79 ih 43 Models for Unconventional Batch Distillation 85 431 Continuous Column for Batch Distillation 85 432 Inverted Batch. Modeling aspects are discussed and a suitable representation for operations is introduced. A batch still with a 50 gallon pot. Home Distiller View Topic Still Design Opinions Moonshine Still Distilling Alcohol Home Brewing Beer.

However the design of a batch distillation system is more complicated because of the transient nature of the operation and because there may be several ways in which the overall separations required may be accomplished. 2 Operation under total reflux with sol-vent-feedingoo S0. Wankat discusses batch distillation an important part of the production of seasonal or low capacity and high-purity chemicals and is a very frequent separation process in the pharmaceutical industry. Batch distillation refers to the use of distillation in batches meaning that a mixture is distilled to separate it into its component fractions before the distillation still is again charged with more mixture and the process is repeated. R LD 6. Design of batch distillation. Distillation Reflux Principle Distilling Alcohol Distillation Moonshine Still.

And summary of operation was compiled. The batch distillation process has existed for many centuries. Number of stages or plates in the column section and thereby the column height 2. Thus the design and mode of operation of many existing batch stills has evolved on a empirical basis with only limited reference to conventional distillation engineering calculation. Following these initial attempts of the reboiler and the McCabe-Thiele operating line Westerbergs group at Carnegie Mellon University quasi-steady-state assumed have been rederived for developed the concept of the reactive difference point7 reactive batch distillation columns. Imperial College Press Jan 1 2004 - Technology Engineering - 396 pages. Fractionating Column Distilling Alcohol Homemade Alcohol Beer Brewing Kits.

Number of stages or plates in the column section and thereby the column height 2. Mujtaba and Macchietto 1993. Reboiler size batch size and heat transfer area 4. Thus the design and mode of operation of many existing batch stills has evolved on a empirical basis with only limited reference to conventional distillation engineering calculation. A batch still with a 50 gallon pot. The most outstanding feature of batch distillation is its flexibility. Home Distillation Of Alcohol Homemade Alcohol To Drink Distillation Homemade Alcohol Home Brewing.

Logsdon and Biegler 1993. Modeling aspects are discussed and a suitable representation for operations is introduced. Batch distillation refers to the use of distillation in batches meaning that a mixture is distilled to separate it into its component fractions before the distillation still is again charged with more mixture and the process is repeated. The design of a batch distillation column is similar to the design of a continuous distillation column in that the following main design parameters must be determined. Introduction 276 KB Request Inspection Copy. The batch distillation process. Image Result For Copper Reflux Still Plans Pot Still Moonshine Still Plans Homemade Still.

Reflux ratio D L R. The process variables are interdependent as determined by the mass and energy balances and the mode of operation. Batch distillation refers to the use of distillation in batches meaning that a mixture is distilled to separate it into its component fractions before the distillation still is again charged with more mixture and the process is repeated. And summary of operation was compiled. Reboiler size batch size and heat transfer area 4. Due to the dynamic behavior of the operation of batch distillation that leads to more difficult operation such efforts have been done to attain the desired specifications and at the same time to increase the operability. Sieve Design Distillation Distilling Alcohol Homemade Alcohol.

Thus the design and mode of operation of many existing batch stills has evolved on a empirical basis with only limited reference to conventional distillation engineering calculation. The process variables are interdependent as determined by the mass and energy balances and the mode of operation. Modified steps of the variable reflux operation. Because this batch column essentially performs the rectifying operation it is often referred to as a batch rectifier. 3 Operation under finite reflux ratio with sol-vent-feeding0. Techniques for the dynamic simulation and optimization of the operation are reviewed in particular the control vector parameterization. Ginuary Ginuary2017 Ginfacts Gin Ginspiration The Gin Making Process As An Infographic From The Brilliant Gin Making Process Gin Distillery Distillation.

Techniques for the dynamic simulation and optimization of the operation are reviewed in particular the control vector parameterization. Number of stages or plates in the column section and thereby the column height 2. 4 Operation under finite reflux ratio without solvent. Following these initial attempts of the reboiler and the McCabe-Thiele operating line Westerbergs group at Carnegie Mellon University quasi-steady-state assumed have been rederived for developed the concept of the reactive difference point7 reactive batch distillation columns. Whilst this is a particularly valid approach when the vapor-liquid equilibria are unknown it relies on both experience and availability of suitable plant to get a practical separation scheme. Wankat discusses batch distillation an important part of the production of seasonal or low capacity and high-purity chemicals and is a very frequent separation process in the pharmaceutical industry. Continuous Distillation Wikipedia The Free Encyclopedia Distillation Distilling Alcohol Chemical Engineering.

3 Operation under finite reflux ratio with sol-vent-feeding0. 1 SCOPE This Engineering Guide sets out the factors which can influence the design of a batch still facility. In batch distillation columns the feed may be charged into the reboiler at the beginning of the operation and then heat is provided at the reboiler to evaporate part of the liquid to generate a vapor that rises through the column until it reaches the condenser where it is converted to liquid and collected at the reflux tank. This flexibility allows one to deal with uncertainties in feed stock or product specification. Techniques for the dynamic simulation and optimization of the operation are reviewed in particular the control vector parameterization. The efforts include both the design and operation of batch distillation. Unit Operations In Food Processing R L Earle.

Because this batch column essentially performs the rectifying operation it is often referred to as a batch rectifier. 1 SCOPE This Engineering Guide sets out the factors which can influence the design of a batch still facility. Imperial College Press Jan 1 2004 - Technology Engineering - 396 pages. Logsdon and Biegler 1993. Wankat discusses batch distillation an important part of the production of seasonal or low capacity and high-purity chemicals and is a very frequent separation process in the pharmaceutical industry. And used this concept to provide simplified design With respect to the limiting operation conditions. Reflux Column With Packing Material Distillation Copper Pot Still Chemistry Lessons.