ammonia air stripping design Ammonia stripping is a simple desorption process used to lower the ammonia content of a wastewater stream. Volatile compounds have relatively high vapor pressure and low aqueous solubility characterized by the compounds Henrys law coefficient which is the ratio.

Ammonia Air Stripping Design, Delta Cooling Towers Inc. The first pilot and full-scale am monia. This study reports an ammonia removal by an air stripping tower which is filled up with packing bed Intalox Saddles.

Matt The Alchemist On Instagram Which Is Your Favourite One Alchemic Symbols Symbols Alchemist From pinterest.com

Matt The Alchemist On Instagram Which Is Your Favourite One Alchemic Symbols Symbols Alchemist From pinterest.com

Stripping air flow rate. When thermal air stripping was chosen in 1997 as the. The OxyStrip Air Stripping system is the only truly non-clogging non-fouling air stripper in the marketplace. A sensitivity analysis was also done to make sure the column could withstand changing conditions like temperature and contaminant concentration. It is often easier and less expensive to remove nitrogen from wastewater in the form of ammonia than to convert it to.

Designed and fabricated 1 one 9-0 Diameter x 29-0 high air stripping tower to treat 70gpm of Ammonia contaminated water at the Coey Tanning Company factory in Wartrace TN.

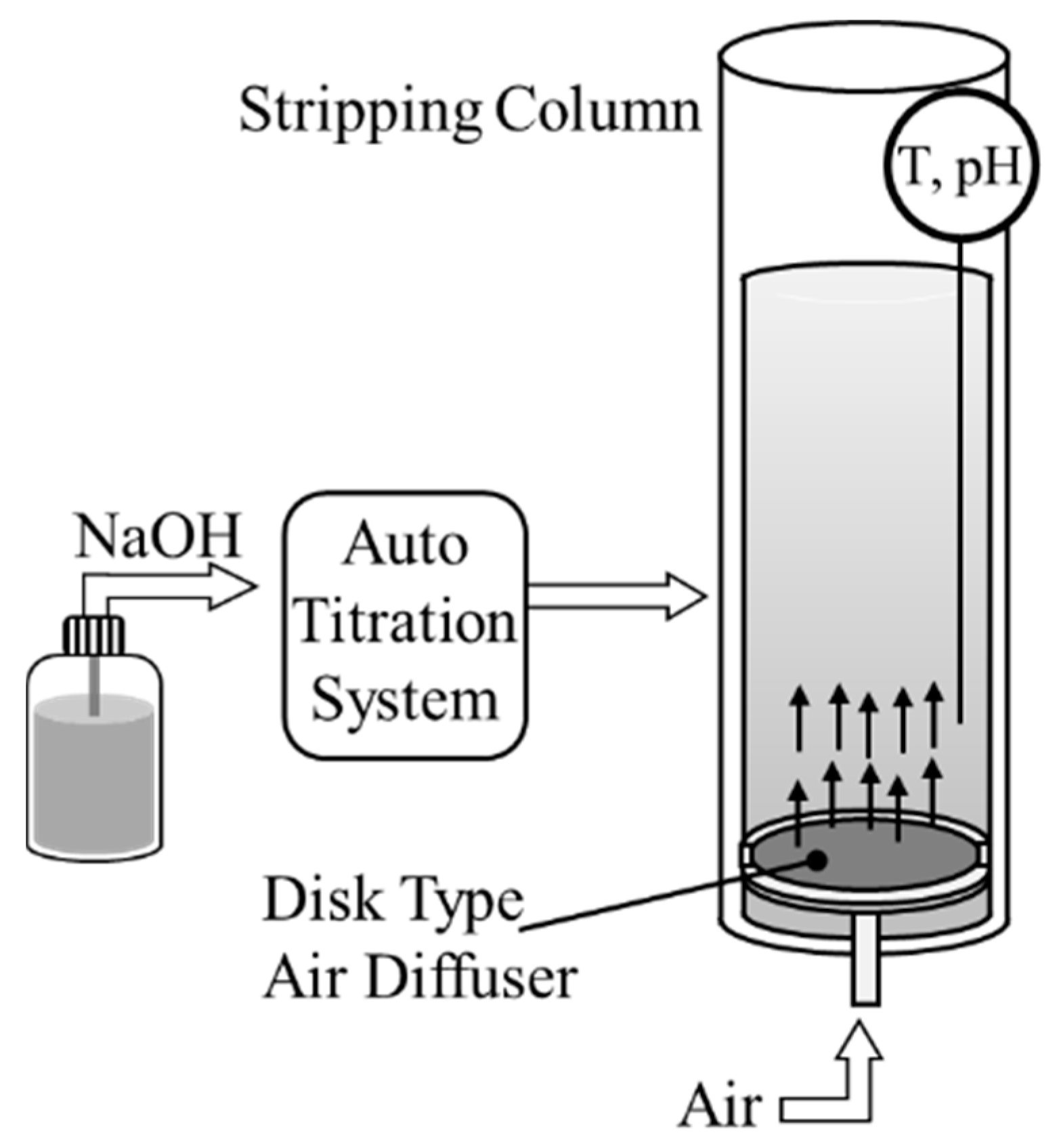

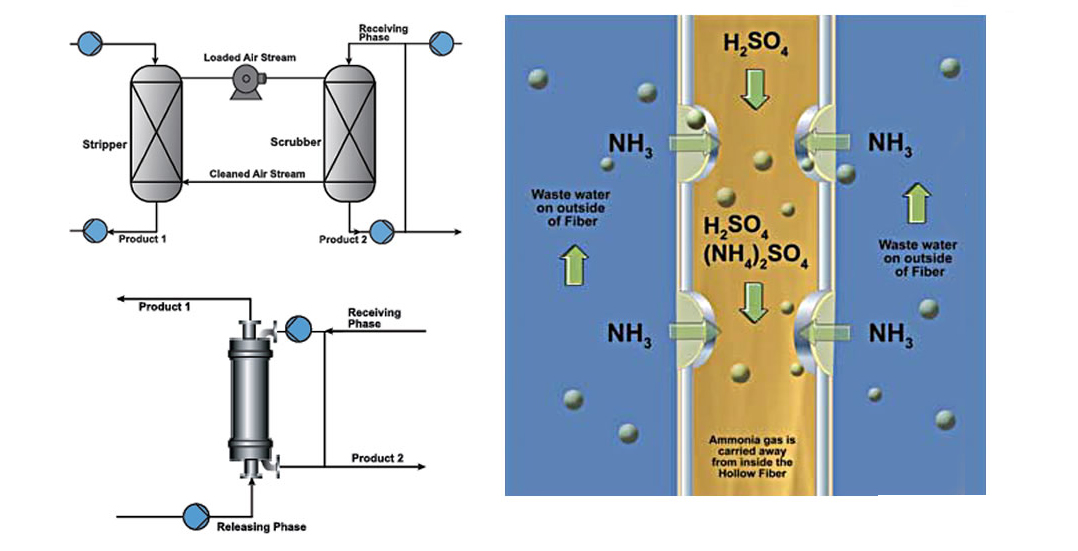

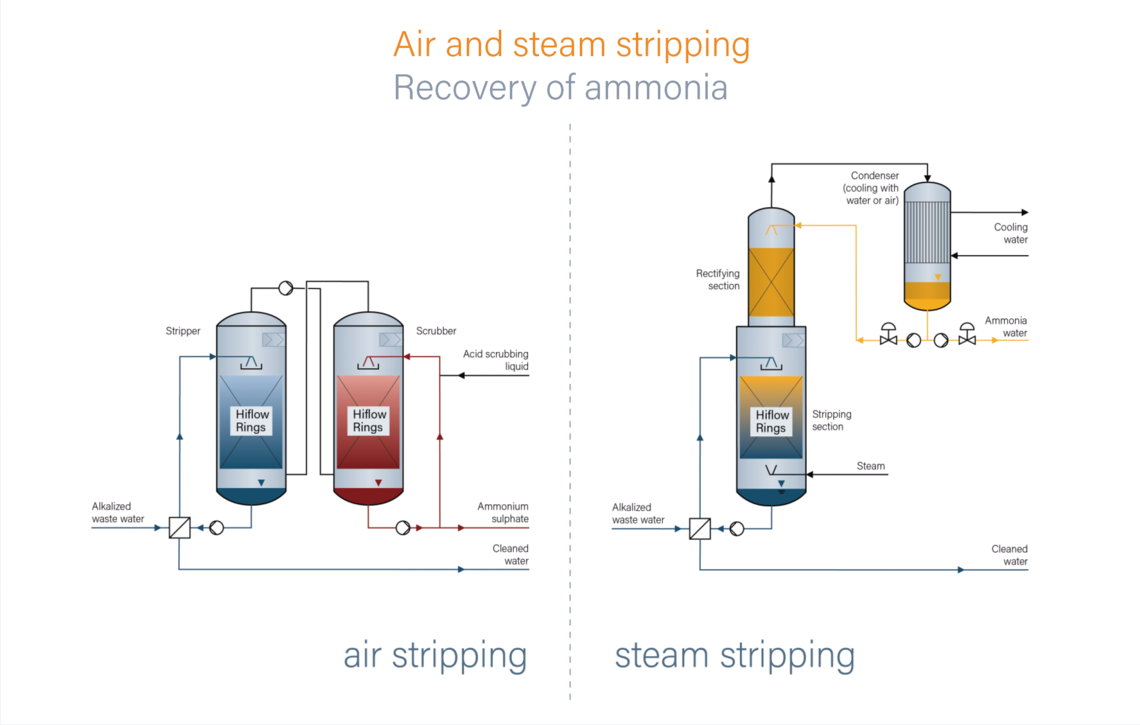

STRIPPER DESIGN In the stripper the pH and temperature are adjusted before the water enters the stripper. Various approaches exist including air stripping steam stripping and membrane to name a few. Ammonia air scrubbers incorporate a variety of gas-liquid contacting techniques including packed beds spray chambers and water jets. A process which in addition requires reduced investment and operating costs compared to conventional solutions. This tower is an apparatus that removes only isolated NH3 by air stripping.

Another Article :

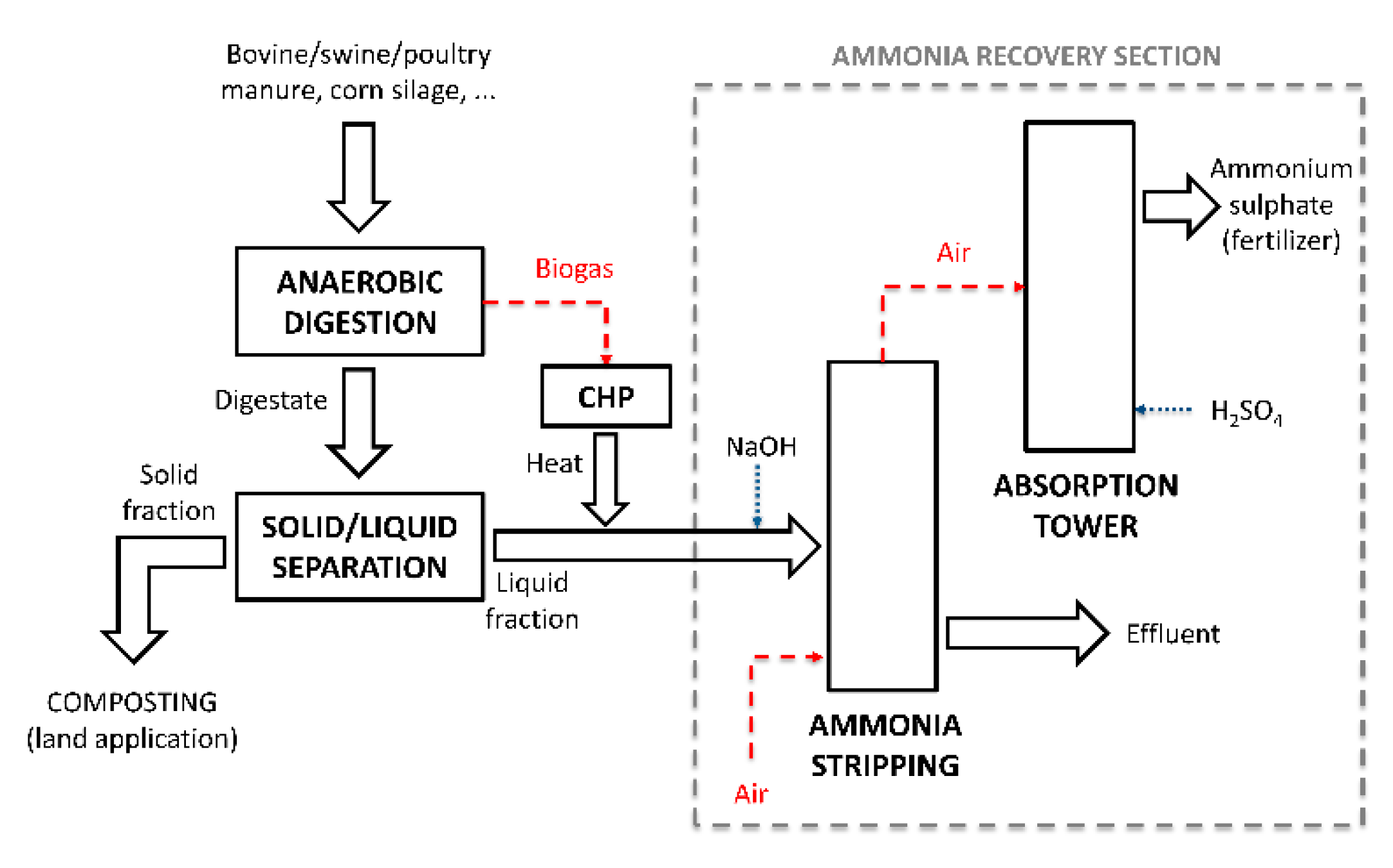

The overall basis for design of the counter-current packed-bed air stripping tower is presented in Section 103 of Process. It is proved that the steam stripping shows better operability and economic performance than the air stripping. The air stripper shell was fabricated from FRP and was supplied with a centrifugal blower was designed to produce 1875cfm at 25 wc. When thermal air stripping was chosen in 1997 as the. Stripping air flow rate. The first pilot and full-scale am monia. Simplified Ammonia Stripping Process Source Own Elaboration Download Scientific Diagram.

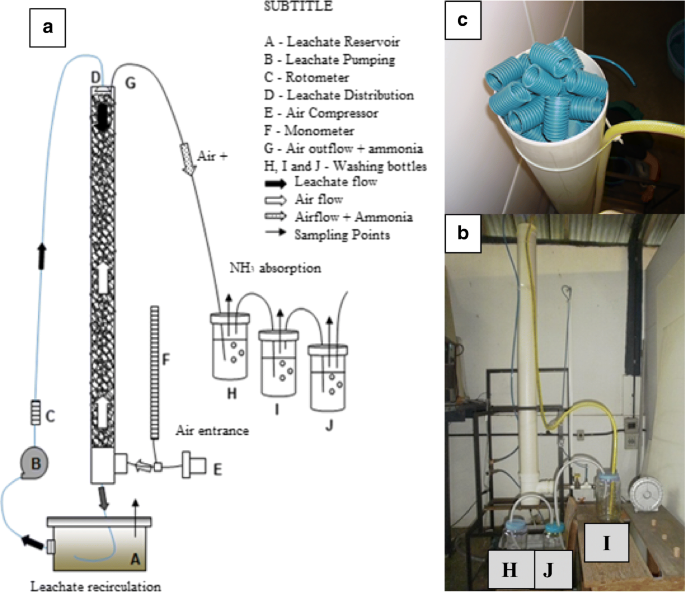

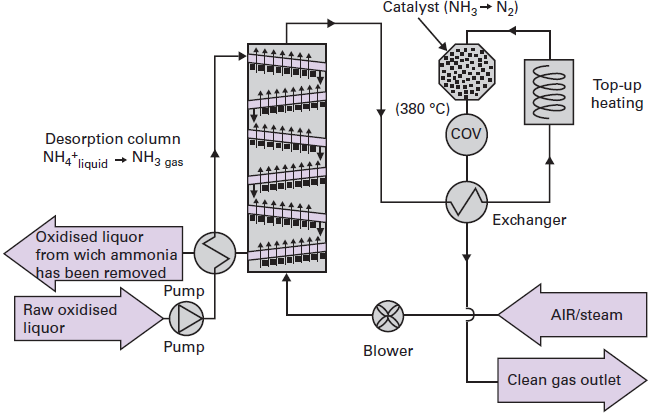

Air stripping of ammonia is generally carried out in stripping tanks and packed towers. Based on the results as the contact time and pH increase the removal efficiency of ammonia increases which showed the effect of these two important factors on the efficiency of ammonia removal through air stripping. Three basic ammonia stripping systems have been developed investigated and applied mainly in the U. In designing an ammonia air stripping tower the students had to understand and use their knowledge of system and process characterization and modeling fluid flow and mass transport interface mass transfer and reaction equilibria and thermodynamics. Removal is applied for the design of a steam stripper. The most economical method for the treatment of ammonia pollution. Pdf Recent Development In Ammonia Stripping Process For Industrial Wastewater Treatment Semantic Scholar.

The mass transfer coefficients of some typical stripping processes are compared in Table 1. This tower is an apparatus that removes only isolated NH3 by air stripping. Actual design to obtain more than 90 ammonia-stripping eff iciency it has been recom- mended that the design air requirement be 15 times the theoretical value 14. They are briefly described below. The design ensures that the air collects up to 985 of the ammonia gas into the air. Design adapted to the site complying with safety standards. Byoflex Unique Solutions For Ammonia Stripping.

They are briefly described below. Ammonia is a very soluble gas in water. The air is then passed directly to a thermal oxidiser where it is combusted destroying the ammonia and releasing nitrogen carbon dioxide and water to the atmosphere see Figure 2. Air enters the bottom of the tower from a fan and travels upward through the packing. In vitro removal the study has revealed that the. The overall basis for design of the counter-current packed-bed air stripping tower is presented in Section 103 of Process. Applied Sciences Free Full Text Influence Of Ammonia Stripping Parameters On The Efficiency And Mass Transfer Rate Of Ammonia Removal Html.

1 and 801 Can be used to remove. It is a process by which wastewater is contacted with air to strip the ammonia gas present in the wastewater. Air stripping of ammonia is generally carried out in stripping tanks and packed towers. Air stripping efficiency is limited by the volatility of the contaminant Volatility tendency of a compound to evaporate under normal atmospheric conditions More likely to become gas when more volatile Extremely efficient at removing volatile organic compounds VOCs Can be used for semi-volatile compounds with. In vitro removal the study has revealed that the. It is an environmental engineering technology used for the purification of groundwaters and wastewaters containing volatile compounds. Enpureusa S Membrane Contactors Designed For Ammonia Removal Solutions.

S South Africa and Israel. Ammonia is a very soluble gas in water. In addition the results of the design performed to remove ammonia using air stripping are shown in Table 8. It is proved that the steam stripping shows better operability and economic performance than the air stripping. S South Africa and Israel. The mass transfer coefficients of some typical stripping processes are compared in Table 1. Upgrading Of Biogas By Utilizing Aqueous Ammonia And The Alkaline Effluent From Air Stripping Of Anaerobically Digested Animal Manure Application On The Design Of A Semi Industrial Plant Unit Sciencedirect.

At the same temperature using the WSA to strip ammonia can get a higher mass transfer coefficient than using other traditional equipments in addition the air consumption is. Some wastewaters contain large amounts of ammonia andor nitrogen-containing compounds that may readily form ammonia. Packing of the stripping tower. The stripping column was designed to meet the specifications set in the design conditions while also being as cost-effective as possible. It is an environmental engineering technology used for the purification of groundwaters and wastewaters containing volatile compounds. It is often easier and less expensive to remove nitrogen from wastewater in the form of ammonia than to convert it to. Ammonia Recovery From Air Stripping Process Applied To Landfill Leachate Treatment Springerlink.

Stripping air flow rate. The air is then passed directly to a thermal oxidiser where it is combusted destroying the ammonia and releasing nitrogen carbon dioxide and water to the atmosphere see Figure 2. As the water is distributed over the internal packing media it is broken up into small droplets which create a tremendous amount of surface. DESIGN CRITERIA The following criteria should be considered when designing ammonia stripping systems. They are briefly described below. In vitro removal the study has revealed that the. Advanced Ammonia Nitrogen Removal And Recovery Technology Using Electrokinetic And Stripping Process Towards A Sustainable Nitrogen Cycle A Review Sciencedirect.

The overall basis for design of the counter-current packed-bed air stripping tower is presented in Section 103 of Process. Air stripping of ammonia is generally carried out in stripping tanks and packed towers. The most economical method for the treatment of ammonia pollution. Stripping air flow rate 32 to 54 lminm3 or 300 to 500 ft3mingal. RECOVAMMONIA TM solution Ammonia waste recycling. The air stripper shell was fabricated from FRP and was supplied with a centrifugal blower was designed to produce 1875cfm at 25 wc. Removal Of Ammonia And Benzene Type Compounds From Branch Environmental Corp.

Air stripping efficiency is limited by the volatility of the contaminant Volatility tendency of a compound to evaporate under normal atmospheric conditions More likely to become gas when more volatile Extremely efficient at removing volatile organic compounds VOCs Can be used for semi-volatile compounds with. Actual design to obtain more than 90 ammonia-stripping eff iciency it has been recom- mended that the design air requirement be 15 times the theoretical value 14. DESIGN CRITERIA The following criteria should be considered when designing ammonia stripping systems. Based on the results as the contact time and pH increase the removal efficiency of ammonia increases which showed the effect of these two important factors on the efficiency of ammonia removal through air stripping. Delta Cooling Towers Inc. When thermal air stripping was chosen in 1997 as the. Air Stripping Tower Water Storage Wastewater Clear Water.

S South Africa and Israel. The overall basis for design of the counter-current packed-bed air stripping tower is presented in Section 103 of Process. Ammonia-N stripping is a mature technology that is used extensively in commercialindustrial applications but has seen little uptake in animal agriculture to date. This study reports an ammonia removal by an air stripping tower which is filled up with packing bed Intalox Saddles. These are air stripping towers forced stripping mechanically aerated ponds and free stripping non-aerated ponds. Ammonia is a very soluble gas in water. Ammonia Recovery Rvt.

DESIGN CRITERIA The following criteria should be considered when designing ammonia stripping systems. Optimum conditions are noted in parentheses. S South Africa and Israel. When thermal air stripping was chosen in 1997 as the. The stripping column was designed to meet the specifications set in the design conditions while also being as cost-effective as possible. Air enters the bottom of the tower from a fan and travels upward through the packing. Pdf Recent Development In Ammonia Stripping Process For Industrial Wastewater Treatment.

Ammonia stripping is a simple desorption process used to lower the ammonia content of a wastewater stream. The ammonia stripping process is based on the principle of mass transfer. DESIGN CRITERIA The following criteria should be considered when designing ammonia stripping systems. The design ensures that the air collects up to 985 of the ammonia gas into the air. Ammonia is a very soluble gas in water. The air is then passed directly to a thermal oxidiser where it is combusted destroying the ammonia and releasing nitrogen carbon dioxide and water to the atmosphere see Figure 2. Aquaculture Effluent Treatment With Ammonia Remover Bacillus Albus Assf01 Sciencedirect.

In vitro removal the study has revealed that the. It is often easier and less expensive to remove nitrogen from wastewater in the form of ammonia than to convert it to. Ammonia air scrubbers incorporate a variety of gas-liquid contacting techniques including packed beds spray chambers and water jets. RECOVAMMONIA TM solution Ammonia waste recycling. The presence of ammonia in wastewater can be found in two forms namely ammonium ions and ammonia gas. A sensitivity analysis was also done to make sure the column could withstand changing conditions like temperature and contaminant concentration. Sustainability Free Full Text The Valorization Of Ammonia In Manure Digestate By Means Of Alternative Stripping Reactors Html.

Removal is applied for the design of a steam stripper. The first pilot and full-scale am monia. Types of aeration methods include packed towers diffused aeration tray aeration and spray aeration. Ammonia-N stripping is a mature technology that is used extensively in commercialindustrial applications but has seen little uptake in animal agriculture to date. The OxyStrip system has been used to strip ammonia from Leachate and VOCs and CO2 from groundwater that would destroy a typical air stripper in a matter of days. Hydraulic wastewater loading 01 to 02 lminm3 or 1 to 2 galminft2. Ammonia Treatment Degremont.